After several years of operating at losses under previous Malaysian Managers, the PSC Tema Shipyard seem to be recovering from its dark and gloomy days and is seeing a new lease of life that is characterized by latest innovations and seamless efforts to completely change the way things were done at the Shipyard in the past.

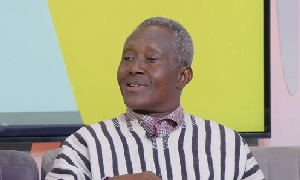

After posting an impressive profit after tax of 21%, 24% profit before tax and gross profit of 53% in the first quarter of the year, one can reliably conclude that the company is indeed bouncing back to more viability and profitability under its new Chief Executive Officer, Mr. HRT Ali. His bottom up approach, all hands on deck, improved communication, transparency strategy has worked in transforming the yard.

The shipyard in the past reeled under serious and dire financial constraints and was a hotspot for incessant industrial upheavals by the local union at the company yearning for good leadership often resulting in disruptions in productivity among others, but has seen so much calmness and increased productivity leading to quick turnaround time over the last 10months since he took office. Mr. Ali, an astute industry guru in charge and a results oriented person.

Change in payment policy

Since taking over the headship of the company, one of the first moves Mr. Ali made was to change the payment policy of the company which gave clients (ship-owners) the leeway to have their vessels repaired for them and paid later and almost always at their convenience, a situation that put a lot of stress on the finances of the company.

The move, Mr. Ali, made was to change the payment policy by ensuring that all clients make 100% down payment before work begins on their vessels at the shipyard. This new policy, it was feared by many workers would backfire and that the company was going to lose most of its clients, but it has proven to be the best decisive decision ever to be taken by the Chief Executive Officer.

The company has been able to retrieve some of its account receivables owed by its customers which was estimated to be in the region of 1million dollars or more.

All of the company’s clients are also complying with the directive regarding the payment policy and both parties (the company and clients) seem to be quite happy with the current arrangement, and also swift attention to customer complaints, resulting in a quick turnaround in the fortunes of the once depressed PSC Tema Shipyard,.

Streamlining of procurement procedures

Another issue that caught the CEO’s attention was the way procurement was a "one man" show, he immediately constituted a 7member procurement committee in line with PPA requirement. He is ensuring procedures are being followed in all areas.

It is believed that the company lost a lot of revenue through dubious invoicing and inflation of figures for prices of procured items among others.

Being mindful of the fact that the company needed to operate in tandem with international best practices. He has plugged holes which was a drain on the company.

The procurement committee ensures all processes and procedures followed to the letter, thereby saving the company so much money that hitherto leaked through dubious procurement practices.

All hands on deck

Operating an open door policy, Mr. Ali was able to rally all the workers of the company together by ensuring that all their concerns always receive urgent attention since he believes the human resource base of the company is its backbone.

The once boisterous shipyard has become a quiet and calm environment eliciting the best of the energy of the workers who are more than willing to give off their best taking cognisance the fact that management was inclining its ear to their complaints and attending to them swiftly upon reaching his desk.

The general impression one gets these days at the shipyard is that a very conducive environment has been created to ensure that uninterrupted work takes place always.

Quick turnaround time

The PSC Tema Shipyard has become the centre of attraction for ship-owners who ply the coast of Africa because of measures that have been instituted to ensure quick turnaround time. Vessels that could take up to 45 days to be worked on are now done in two weeks and at most 20 days.

Mr. Ali tells Maritime and Transport Digest that countries such as Greece and Turkey among others have called the company and indicated their readiness to use the shipyard because of the quick turnaround time.

An interesting dimension that makes the operations of the workers unique is the quest for excellent and perfect finishing, a virtue that the workers insist on at all times.

According to Mr. Ali, the shipyard has been fully booked until the end of August this year, adding that there were a host of vessels that were also planning to use the facility even after the August period.

Training

Training according to Mr. Ali would take centre stage in the life of the company with the view to ensuring that workers all of whom are Ghanaians acquire that requisite knowledge and skills that will enable them deliver effectively and efficiently,

‘’ I have started training seriously and one of my guys is going to South Africa in August to do the non distractive testing (NDT) training which forms a core part of our operations. He is expected to impart this knowledge to his colleagues on return and this is the way we believe we should be going’’

We have carried out, training on Change Management, Drug and Alcohol Abuse, Maritime Security, Procurement, Internal Audit and Human Resource. The training is ongoing.

Rebranding and Marketing

The shipyard according to Mr. Ali would be rebranded in the next couple of months including a change in name and then to be followed by a series of marketing campaign geared towards advertising the shipyard especially to the international shipping community.

The drive for marketing of the company would start with visit by Mr. Ali to neighbouring West Africa countries next week, adding that other areas management was looking at working on is to retooling the company to get it to operate at full capacity.

Some of the company’s machines which have been lying idle for some time now would be serviced, and the management is also ready to capture a fair share of the fabrication market which has proven to be a very competitive one.

The company has already put up adverts in international magazines which would be out next month as shipping is global and international in nature.

Business News of Monday, 16 June 2014

Source: Maritime & Shipping Digest