We, the authors of the book The Quest for Nuclear Power in Ghana, have followed with keen interest the April 24, 2024, news coverage of the cooperation and framework agreement between the Ghana Ministry of Energy and the China National Nuclear Corporation (CNNC) for the construction of an HPR 1000 technology nuclear power project. According to the news account by the Ghana Broadcasting Corporation and GhanaWeb, the agreement was approved by the Ghana cabinet and signed on the margins of the 26th World Energy Congress in Rotterdam, Netherlands, by Ghana's Energy Minister Dr. Matthew Opoku Prempeh and CNNC President Mr. Yu Jianfeng, for constructing an HPR 1000 nuclear power plant and upgrading Ghana's electrical grid.

Yes, we agree with the conventional wisdom that we need to remove import duties on solar panels, wind, and other renewable energy systems, and even on electric cars, to encourage individuals who can afford them to purchase and install these systems in their homes and small businesses, and thus lessen the demand on power from ECG. However, for huge industrial and manufacturing plants, large power sources, including nuclear power, must be considered.

The merits of nuclear power are overwhelming; what most people worry about are the safety issues, so in this article, we would like to provide a basic understanding of the technology used in HPR 1000 and how the safety issues have been taken care of.

With regard to the nature of the agreement itself, we are obviously not in a position to make any detailed comments since we are not privy to the agreement. However, it is obvious that Ghana is currently not in a sound economic position to proceed with the purchase of a nuclear power plant, so the most likely possibility for “purchasing” a plant of this size is via the vehicle of BOOT (Build, Own, Operate, and Transfer), such as was done with the AMERI power plant, which is now owned by Ghana and part of which has been reinstalled at Kumasi.

In our book, The Quest for Nuclear Power in Ghana, we discussed issues of nuclear reactor safety, the siting of nuclear reactors, management, and the eventual safe return of spent nuclear fuel and waste generated to the supplier country for safe disposal or reprocessing. Most importantly, the authors described and recommended small modular reactors (SMRs) as supported by the IAEA because their designs ensure passive inherent safety features, meaning they cannot explode or create serious accidents like what happened in Fukushima (Japan), Chornobyl (USSR), and the Three-Mile Island (USA). The HPR 1000 Chinese reactor has both active and passive safety features, which assure a very safe operation. It is the intent of this article to briefly discuss how these safety

issues have been addressed in the HPR 1000.

What is a nuclear power plant?

In general, a nuclear power plant is a device that generates a tremendous amount of heat to boil water to steam. The high-pressure steam is used to turn a turbine connected to a generator to generate electricity. The source of heat (that is, the fuel) is typically uranium, whose atoms have the unique ability to spontaneously break apart, knocking other atoms apart as well. This process of spontaneously breaking apart atoms is referred to as “fission.” A lot of heat is generated during this fissioning process.

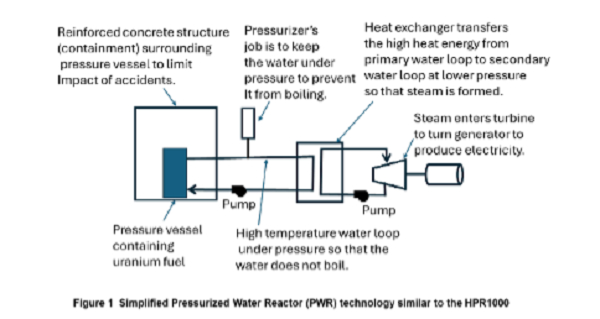

While this is the basic process for generating heat in a nuclear power reactor, the two well-proven techniques for carrying the heat from the reactor core to generate steam are pressurized water reactors (PWRs) and boiling water reactors (BWRs). [Both PWRs and BWRs use water for the generation of steam, so they are collectively referred to as Light Water Reactors (LWRs)]. Since the HPR 1000 uses PWR technology, we will focus on this technology.

Figure 1 shows a simplified diagram of a PWR. For brevity in this article, the reader is referred to the annotations on the figure for a better understanding of how the PWR generates electricity.

The HPR 1000 Nuclear Power Plant:

The HPR 1000 is what is referred to as a Generation III PWR (Gen III PWR). At this point, it is helpful to explain what this means. The earliest prototype reactors were developed in the United States in the 1940s and 1950s and are referred to as First Generation (Gen I) nuclear power plants. Commercial

plants followed from the 1960s through the 1980s and are referred to as second-generation (Gen II) plants The majority of nuclear power plants still in operation today are Gen II plants.

However, since the early 1990s, LWRs have undergone evolutionary improvements. These include inherently safe operation or improved safety features, greater protection against severe accidents, etc. As an example, one measure used in assessing a nuclear reactor’s robustness against accidents is the core

damage frequency (CDF). This is the likelihood of an accident that would cause damage to the reactor core (see blue area in Figure 1) during the reactor’s operating life. For Gen III and III+ plants, the CDF has been estimated at between 10 and 100 times (depending on the design) lower than that for Gen II plants.

This means that Gen III and Gen III+ plants are 10 to 100 times less likely to have an accident that will cause damage to the reactor core during the operating life of the reactor. Now let us examine how nuclear power plants in general, and the HPR 1000 in particular, are designed to first try to prevent accidents from happening and, in the event that they do happen, how the plant is designed to mitigate them.

First, control the reactor to prevent over-generation of neutrons (power) during normal operation.

Second, remove heat from the core if a lack of reactivity control or other factors causes the core to overheat.

Third, limit the release of radioactivity in case of an accident, such as if there is a large break in the primary piping and heat cannot be removed from the core fast enough

Fourth, ensure that heat can be removed from the spent fuel at all times

As for Gen II plants, the HPR 1000 has design features that address all the above. However, the HPR 1000 goes beyond that by using Gen III design methods to achieve a much greater level of reliability, robustness, and safety, such as the reduction in core damage frequency mentioned above. Some of the methods used in the design include the following:

Use of Redundancy: This means using a second (backup) method to achieve the same safety function in case the first method fails to work properly.

Use of Diversity: This means using a different kind of technology, equipment, or method to achieve the same safety function. The objective is to reduce the chances that some kind of common-mode failure (a failure that may be common to similar equipment) strikes all equipment at the same time when it is most needed. For example, in the HPR 1000, both active and passive features are employed to guarantee safety functions, including emergency core cooling and containment heat removal. Note that passive safety refers to safety

feature that does not require operator action or electronic circuitry to initiate shutdown safely in the event of an accident, such as a loss of coolant.

Thus, passive safety designs exploit laws of physics, such as gravity, pressure differences, or natural heat convection, to maintain a safe state without the use of any active control components. Thus, if an accident requires that a system be flooded with water, an active safety feature may require a pump to pump water into the system, whereas a passive safety feature may include an elevated water tank that floods the system by gravity as a backup provision.

Use of Independence: Independence means making sure that redundant systems don’t have any dependence on each other; otherwise, the reliability of the safety system achieved by using redundant systems will be compromised. In the HPR 1000, the independence of redundant safety systems is ensured by arranging each equipment train in a physically separate building and supplying power from separate sources.

The above measures are all part of a defense-in-depth (DiD) approach to the design of a nuclear power plant, which, based on a study of the available information on the HPR 1000, has been employed in the design of this nuclear plant. (DiD design philosophy is defined as the creation of multiple independent and redundant layers of protection and response to failures and accidents.)

Space will not allow us to go into any further details regarding particular safety features of the HPR 1000, so at this point, we believe it will be appropriate to turn our attention back to the BOOT type of contract alluded to earlier and the matter of radioactive waste disposal.

Which way forward...? Our considered opinion:

We emphasize that we do not know the actual type of contract under which this project will be implemented. We can only state our opinion that the BOOT type of contract is the only one that makes sense, given that there is absolutely no money to buy it ourselves under any other type of contract. However, there are downsides to a BOOT contract too. Because the other party is providing all the resources, there is possibility of raising utility costs to recoup investments, potential refusal to hire Ghanaians in management positions, any lack of conscious technology transfer, etc.

The BOOT contract also requires greater scrutiny and regulatory oversight to safeguard Ghana's interests. Given the country's track record in less than transparent deals, a long-term BOOT contract may also be prone to all kinds of oversight requirements "falling through the cracks." This may be especially

true when the government changes hands, with the attendant change of oversight leadership. Given the importance of such an investment, we hope that there will be long-term oversight, independent of which government is in power. The issue of what to do with the spent fuel is also one of the big issues in operating a power reactor anywhere, but especially in a developing country such as Ghana.

Why is there spent fuel in the first place? Spent nuclear fuel is the fuel (uranium rods) that has been operating in the reactor for a long time until it is no longer useful for sustaining the nuclear fission chain reaction in the reactor. Spent fuel is thermally hot as well as highly radioactive. They are typically stored in spent fuel pools at the reactor site for long periods of time. However, a place for long-term storage must eventually be found. In a developing country like Ghana with no facility for any long-term storage, it is the opinion of the authors that the eventual transportation of the spent fuel to the vendor country (China in this case) should be part of the agreement.

Opinions of Tuesday, 14 May 2024

Columnist: Dr. Kofi Korsah, Eng. Laala Anum, Prof.J.H. Amuasi